Pump Technology

Our concrete pumps (as well as our sludge pumps) are hydraulically driven, twin-cylinder pumps. Their hydraulic drive and control systems (called the "brain") have all been designed by SCHWING engineers specifically for applications in concrete and sludge pumps. Because of this, they fulfil more than just the necessary functions of a hydraulic pumping system. The combination of the two systems achieves an extremely steady and gentle pumping pattern, even at maximum outputs.

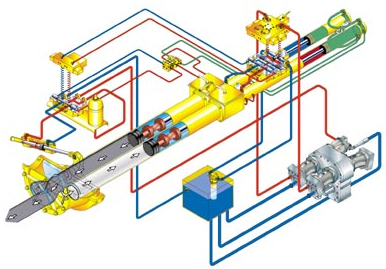

Pump schematic

Hydraulic oil is pumped under pressure to the working cylinders. The hydraulic brain block runs through a compulsory control sequence and extends one of the working cylinders, while the other one retracts at the same time.

This "boxer stroke" is transferred to the concrete pumping cylinders so that one cylinder pumps draws in concrete and the other one pumps concrete into the connected pipeline.

The switch point in the system (the concrete valve) is stroked at the same time to steer the flow of concrete. In the majority of applications, the concrete valve is the famous SCHWING Rock valve.

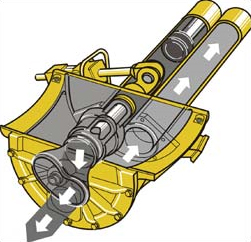

Rock Valve

The SCHWING Rock valve has proven itself over many years and in countless applications to be the epitome of economy in the world of concrete valves. The Rock is robust and easy to service. It is subject to natural wear when pumping concrete and can then be rebuilt with hard-face welding. That makes it multi-economical. A real example of foresighted engineering and value for money.